Hello! Dave here once again. With winter in full force now here in the Midwest it is always good to have a new airplane project to work on to pass the time. Plus with everything else that is happening in the world this is even more so a necessity to keep ones sanity as well. So I thought it best to get this post out about the new motor glider that I have been working on to show everyone what I have been up to.

As most of you have already seen on the blog I have posted several times about the planes that I fly and I have managed to put together a very nice foam core motor glider that I had flown all last year (pictured above). A great plane that has held up very well while learning the ins and outs of flying it. So with this being accomplished I decided to work on a new motor glider that would have a more aerodynamic wing, a fiberglass fuselage, a larger motor and battery along with a folding prop to improve it's glide performance.

Here are a few images of the design that I put together to work out how it would possibly look once completed.

I first started work on the new wing for the plane. I wanted a smoother more aerodynamic wing for the project so I worked on a test part to start. The wing used a proper airfoil for gliders to start. I laser cut out the ribs for the wing that would be assembled in foam core sections. I hot glued most of the wing together as shown above. To seal up the wing the top surface of the ribs were epoxied and the top surface was folded over the entire wing section.

To hold the top surface of the wing in place while the epoxy was drying I taped the end surfaces down and then laid a towel over the wing and then added weight to the wing to secure it. The "Toy" book seemed to be the right choice for pile of books in the photo above.

Here you can see the difference in the smoothness of the new wing compared with the wing on the motor glider I flew last year. Should be a better performer I suspect.

Here the wing sections have been put together and are ready for final assembly. The wing tips were built the same way but are shaped a bit differently than the mid-sections of the wing you see here.The new motor glider wing pictured above was hot glued and taped together to form the entire wing. The assembly went together very well and I am happy how straight the wing turned out along with how light it is. The wing tips shown here are tapered down to a smaller chord length and tipped at a proper angle for stability. The only thing missing in this photo is the 3D printed wing tips that will be added later on in the construction.Next step in the project was to build the mold for the fiber glass fuselage. Here's how this all turned out.

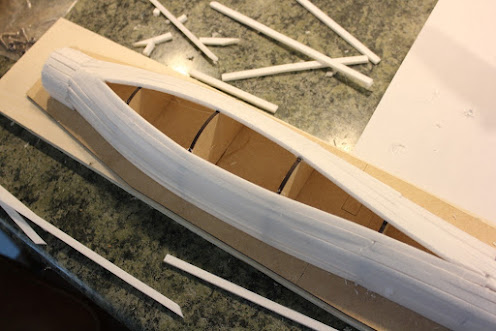

I started with ribs that I laser cut and mounted into slots on a wooden platform. Having designed all of the plane in Fusion 360 it was an easy task to make parts from the computer design. I only needed to make half of the fuselage plug as the top and bottom sections were exactly the same shape to start.

Next I cut 1/4" wide strips of foam core and hot glued them on to the ribs of the form. This took some time and luckily was one of the steps that I find very relaxing to do. Some people can't understand why I say this but it is fun for me to see this type of work start to take shape in a project like this.

With this series of photos the plug for the fuselage is really starting to take shape. Working with the foam core in this manner is very much like creating a wood striped canoe. Same process just different material. Easy to get the compound curves that I wanted for the fuselage plug.

Here the plug for the fuselage mold has finally been covered completely with the foam core strips. The plug at this point was covered with a micro-balloon and resin mixture to fill all the voids that were in between some of the foam strips. After that the plug was sanded smooth to prep it for fiber glassing.

In the three photos pictured above I laid down a couple of layers of 4 ounce fiber glass cloth to give the plug a nice strong surface to start prepping it for more resin/putter mixture and then primer.

Here the fuselage plug has had several sessions of sanding and primer laid down. Other than the glazing (red colored) putty on the part it is starting to smooth out very nicely.

After many sessions of sanding, priming, sanding, priming over and over again the fuselage plug as you see it above was now ready to start making the molds for the fuselage. That's about it for today. I will post the next installment of this project in a few more days once I get all the photos organized to get them ready for the next post. There I will cover the completion of the fuselage and hopefully the final assembly. I will just have to see how long the next post will be once I get that far. Check back soon to see the next installment.

No comments:

Post a Comment